Adhesives distribute loads evenly over a broad area reducing stress on the joint. 2 The LOCTITE Design Guide for Bonding Metals Volume 6 The LOCTITE Design Guide for Bonding Metals Volume 6 3 LOCTITE Adhesive Overlap Weld 14 Nut Bolt Pop Rivets 0 Double-sided Tape 500 1000 1500 2000 2500 3500 4000 4500 Shear Stress lbf 3000 144 252 220 385 260 Advantages of LOCTITE Structural Adhesives vs.

It would be.

. Loctites continuous commitment to improvement insures constant progress of frustration-free dispensing systems and breakthrough formulations. Detailed plastic product design will always require detailed knowledge of the application the processing method and the selected plastic. The Loctite Design Guide for Bonding Plastics Volume 62.

Whether bonding plastic to plastic or other materials adhesives offer several benefits over other joining methods. Like the accelerators primers comprise an active ingredient dispersed in a solvent. The guide also presents shear strength data on 23 Loctite adhesives including cyanoacrylates epoxies hot melts light cure acrylics polyurethanes silicones and no-mixstatic-mix acrylics.

Adhesive permanently bonds difficult-to-bond plastics and rubbers together or in combination with metals andor composites. Loctite Design Guide. For gluing PVC there is a two-part primer and PVC solvent cement commonly available in most hardware or home improvement stores.

Even products which appear to be composed. Plastics have become an integral part of everyday life. Design Guide for Bonding Plastics Volume 5 Cyanoacrylate Adhesives General Description Cyanoacrylates are one-part room-temperature-curing adhesives that are available in viscosities ranging from water-thin liquids to thixotropicgelsWhenpressedintoathinfilmbetweentwosurfaces.

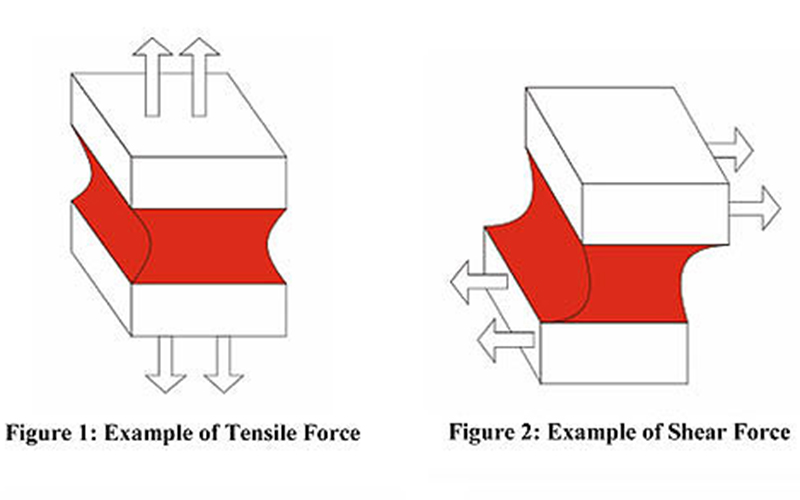

One of these is simply cleaning and abrading the surface. The Loctite Design Guide for Bonding Rubber and TPEs Volume 3 5 Joint Stress Distribution Joint stress distribution is the location of stresses within a bond. The Loctite Design Guide for Bonding Plastics Volume 6 5 Unfilled Resin The unfilled resin used as the base resin for all of the compounded formulations is listed at the top of the table next to each plastic type.

Henkel Corporation Rocky Hill CN has updated and reintroduced its Loctite Design Guide for bonding plastics to simplify the challenge of determining the most effective adhesiveplastic bonding combinations. An informational resource for anyone looking to bond plastics this completely updated 96-page guide provides detailed technical. Exclusively of metals are usually coated sealed or adhesively joined.

The primer will have an on-part life ranging from 4 minutes to 1 hour. The Loctite Design Guide for Bonding Plastics Volume 4 5 Unfilled Resin The unfilled resin used as the base resin for all of the compounded formulations is listed at the top of the table next to each plastic type. Usually expressed as Newtons per square meter NM2 which is equivalent to a Pascal Pa.

To simplify the challenge of determining the most effective adhesiveplastic bonding combinations this company has updated and reintroduced its Loctite Design Guide for Bonding Plastics The 96-page guide provides detailed technical information on the seven leading adhesive technologies that can bond the 30 most common plastic substrates. In bonding plastic feathers and nocks onto arrow shafts 3M Scotch-Weld Industrial Plastic Adhesive 4475 dries quickly to a firm bond that resists plasticizers and water. Class C Components Industrial Hardware Suppliers.

One is actual chemical bonding at the interface of the two resin layers. This high frequency electri-. Look for an adhesive labeled for polyethylene or polypropylene.

Designed for potting and encapsulating applications these two-part room temperature curing products provide excellent peel and shear strength. Each individual formulation was then produced by compounding the unfilled resin with a single additive or filler and was. Information on adhesive types joint design and substrates this guide offers the designer help in choosing the correct solution for their applicat ion.

Loctite Design Guide for Bonding Plastics. For thin bondlines in automotive interior trim attachment 3M Quick Bonding Adhesive. In the English system stress is normally expressed in pounds per square inch psi.

Plexus Adhesives offer a proven solution to the structural bonding of most advanced materials. To-bond plastics and rubbers together or in combination with metals andor composites. For 50 plus years Loctite has delivered customers with innovative sealing and adhesive solutions.

The molecules mix together and the components bond as the solvent dries and evaporates. Acceptable bonding is achieved through a combination of part design material selection mold design and molding process. This guide was designed to demonstrate the basic elements of proper plastic part design.

In solvent bonding the plastic is softened first with a coating of solvent. The Loctite Design Guide for Bonding Plastics provides bond strength data for 30 substrates including ABS delrin nylon polycarbonate polypropylene polyethylene and PVC. However certain items in category 1 may prove impossible to glue.

The other is mechanical bonding which depends on the physical geometry at the interface. Once the carrier solvent has evaporated the surface is immediately ready for bonding. Category 3 PVC is most commonly used in plumbing.

In bonding plastic feathers and nocks onto arrow shafts 3M Scotch-Weld Industrial Plastic Adhesive dries quickly to a firm bond that resists plasticisers and water. They are ideal for. 3M Scotch-Weld Epoxy Adhesive.

In one form or another. Each individual formulation was then produced by compounding the unfilled resin with a single additive or filler and was. LOCTITE urethanes are ideal for bonding metals plastics glass and other substrates.

Standard 50 or 60 Hertz AC line voltage is supplied to the generator power supply and converted to 15000 or 30000 Hertz ie 15 kHz or 30 kHz AC electrical energy. The two plastics components are then clamped together. The Loctite Design Guide for Bonding Plastics Volume 6 81 When poor wetting occurs there are methods to treat the surface for better bonding.

There are two primary ways in which layers bond. Designing Parts for Up Down Molding Helps Control Cost Designing a part that can be molded with a straight pull or up down motion is a great way to keep the cost of the mold down. Difficult to identify a manufacturing process which does not use plastics.

The most common procedure is a solvent wipe followed by. The plastic components mating surfaces joint area so the plastic material will melt and form a molecular bond between the parts. This information can only be provided by raw materials suppliers specialist plastics product designers and plastics processors but there is a need to get the basics of the product design right in the first.

With 5000 plus patents Loctite leads the category and provides the widest line. Depending on the plastic bond strengths of up to 20 the unprimed bond strength can be achieved.

Structural Bonding Alternatives For Plastics Plastics Decorating

Structural Bonding Alternatives For Plastics Plastics Decorating

Structural Adhesive Joint Design Guide

Henkel Loctite Design Guide For Bonding Plastics 2fiftycc Com Home Of The Quarter Litre

Design Guide For Bonding Plastics Henkel Problem 2 The Loctite Design Guide For Bonding Plastics Volume 6 Plastics Have Become An Integral Part Of Everyday Life It Would Be Difficult Pdf Document

0 comments

Post a Comment